| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Techairs

Model Number : SMR

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C

Supply Ability : Negotiable

Delivery Time : Customized

Packaging Details : conventional

product name : 35,000Nm3/H SMR Hydrogen Plant

place : Hebei Xinqiyuan

Purity : ≥99.99%

technology : PSA

raw material : SMR

Advantage : Economical

scale : large

time : 2012

Large Scale Industrial Hydrogen Production Unit From Natural Gas

35,000Nm3/H Large Scale Industrial Hydrogen Production Unit From Natural Gas

Technology Application:

All kinds of hydrogen-rich industrial exhausts (such as chlor-alkali exhaust, coke oven gas, synthetic ammonia tail gas, by-product gas from refining, released gas from methanol, PTA exhaust etc.) are separated and purified for high purity hydrogen through the pressure swing adsorption process, and the technology has reached the world advanced level.

Technical indexes

Purity:99~99.9999%

Capacity:5~100000Nm3/h

Yield:≥90%

Features and advantages

Mature process technology and low costs of hydrogen production.

Wide source of raw material and high purity of product gas.

The Two-high THiPSATM technology is applied.

The special adsorbent has a long service life and low operating costs.

Special programmable control valve is of high automatic degree.

Benefits for customers in hydrogen plant design

Our technology allows for flexible utilization of feedstocks, and designs may be optimized for lowest operating expenditure (OPEX), highest efficiency or lowest total lifecycle cost. Different degrees of modularization and standardization can be applied to meet the project requirements. For all plant designs excelling availability and reliability remains a prime focus. Here customers benefit from Air Liquide’s vast experience in operation with its own large fleet of steam reforming plants.

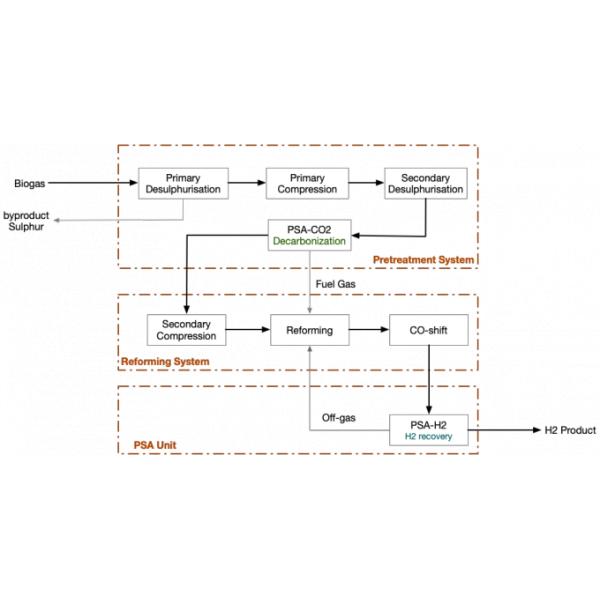

Process Schematic

Desulfurization of feed gas

After raw natural gas is heated to 300~380℃ through convection section of reformer, feed gas will undergo olefin hydrogenation saturation by adding hydrogenation catalyst; meanwhile, organic sulfur will be reformed into inorganic sulfur. After raw material is provided with hydrogenation saturation and organic sulfur is reformed, H2S in feed gas will be desulfurized to 0.1PPm and below through zinc oxide desulfurizing agent, so as to meet requirement of nickel steam reforming catalyst for sulphur. The main reaction (taking mercaptan and thiophene for example) is as follows:

RSH+H2→H2S+RH

C4H4S+4H2→H2S+C4H10

H2S+ZnO→ZnS+H2O

|

|

Large Scale Industrial Hydrogen Production Unit From Natural Gas Images |